Add Protective Coatings to Your Business and Structural Integrity

Introduction:

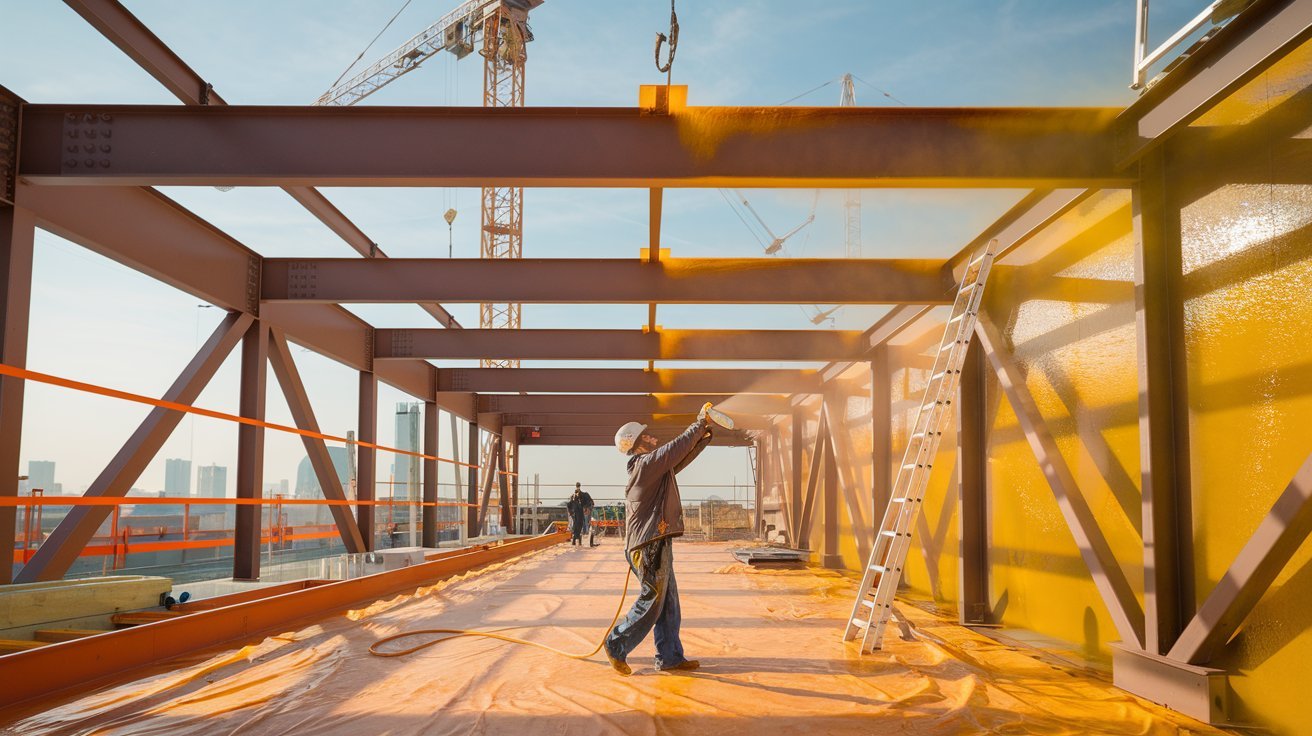

Every building tells its own story, but the scars from time and environmental stress distinguish some tales. Protective coatings can be applied to timber, metal, walls, floors, windows, roofs, and concrete. Structural integrity is crucial for safety, longevity, and effectiveness. The definition and purpose of protective coating is to transform an ordinary surface into a barrier that is against a surface, and protective coatings not only improve aesthetics but also provide critical defense against wear and tear.

Imagine a scenario where buildings maintain their youthful appearance despite enduring extensive weather or industrial use. With the right set of protective coatings, that dream is achievable. As we get deeper into the article, you will come across how these coatings maintain structural integrity and how they are economical in maintenance over some time. Add protective coatings to your business is undoubtedly one of the most intelligent decisions you can make.

We are currently analyzing the reasons for structural deterioration:

Structural deterioration arises from a myriad of factors. One significant factor is environmental exposure, including moisture, fluctuating temperatures, and UV radiation. Every one of these factors causes gradual degradation of materials over time.

Another very important intelligence pertains to chemical reactions occurring within the materials. Corrosion is one such example. It is the reaction of metals, oxygen, and moisture together. All these factors compromise the structural integrity of buildings and infrastructure.

One should not ignore physical stressors as well. Concrete and steel structures are susceptible to cracks and fractures caused by heavy loads and seismic movements.

Moreover, biological factors such as mold growth can incite damage to wooden structures. The damage intensifies with termite infestation, further accelerating decay.

Identifying these causes helps define where greater emphasis should be placed on taking protective measures that reduce those risks while balancing the longevity of construction projects.

The market offers a variety of protective coatings and their applications:

Add protective coatings to your business provide different functional properties for specific applications. For instance, people appreciate epoxy coatings for their toughness and chemical resistance. Therefore, these coatings are used on industrial flooring.

Polyurethane coatings are the best for UV protection and flexibility. This enables use in outdoor settings where sunlight will cause deterioration over time.

Acrylic coatings are fast-drying with relatively sufficient adhesion. They are commonly used in house improvement jobs due to their ability to retain color and provide resistance to climatic elements.

About the marine industry, anti-fouling paints inhibit the growth of algae and barnacles, which attach themselves to every submerged part of a vessel’s hull. Such special formulations guarantee that the optimal performance of the vessel will be maintained for the period it is needed.

Last, but by no means least, fire retardant coatings are a vital component of fire safety measures intended to protect critical load-bearing elements in the event of a fire by shielding them from elevated temperatures. All the cited examples of protective coatings serve the same purpose of increasing the service life of structures in various industries.

The case studies above discuss the various applications of advanced protective coatings that improve structural integrity:

The case study of corrosion on a bridge in an industrial area is of particular note. The application of an advanced polymer coating resulted in an increased lifespan of the bridge. Following this, engineers claimed a 30% decrease in maintenance expenditure.

Another example is a high-rise edifice that had problems with water ingress and the accompanying growth of molds due to a lack of safeguarding. After the application of an innovative elastomeric coating, the structure’s moisture resistance improved drastically, leading to a significant improvement in indoor air quality.

The same thing happened when special anti-fouling coatings made fishing boats in a fleet use less fuel and spend less on drag costs, saving thousands of dollars a year on operating costs.

Such add protective coatings to your business capture distinct obstacles in public service and several other industries that can benefit from improved structural integrity.

There are important traits to examine when selecting a protective coating for your project:

In most cases, coatings serve the same purpose as defense linings. Therefore, when selecting a coating, take into account its durability, flexibility, and temperature range. It guarantees enduring security. The coating chosen ought to be able to withstand severe conditions.

Flexibility is another key feature. Coatings that split apart into fine pieces upon drying on surfaces that expand and contract can also help prevent damage over prolonged periods.

Next, evaluate adhesion properties. Reconsider your beliefs concerning the coating and understand its purpose. While some people think that the surface does not matter much, adhesion to it optimally is equally important.

Most people also consider resistance to chemicals. After the first coating, do other coatings without corrosive solvents justify all the materials used?

Consider the method of application as well. Spraying works best for certain coatings, while rolling off works well for others. Which has a greater benefit given your set of tasks?

Finally, consider the ease with which you can withstand the curing approach and the coating windows; such simple access will provide you with subsequent phases of work without delays.

Observations on the Methods for Optimal Application and Maintenance of Protective Coating:

Similar to other processes, applying protective coatings requires a degree of planning before proceeding. Start by verifying whether the surface is contaminated with materials such as dust, oil, or rust. Any cleaning that increases the adhesion value should be done before everything else.

Additionally, add protective coatings to your business pay attention to the conditions in which the coating is to be applied, as factors like temperature and humidity can greatly affect curing times and effective performance. Whenever applicable, product specifications should be verified.

To coat, employ a constant motion to achieve reasonable coverage. Usually, putting multiple thin layers results in better conditions than a singular thick one. This method increases sturdiness but lessens the potential problems associated with drips or runs.

Once applied, you should maintain the coating with the same care. Consistent checks will help catch any wear or damage early. Making the necessary changes as soon as the damages are spotted will lessen system degradation.

Finally, ensure that all applications and maintenance practices are well documented for better system manageability in the future.

Using protective coatings requires considering sustainability and the environment:

Sustainability remains pivotal across various industries, in this case, protective coatings. Several manufacturers have shifted their focus toward formulations that minimize environmental impacts. These coatings typically have a reduced content of volatile organic compounds (VOCs), which increases safety for workers and nature alike.

We can also gear the application process toward sustainability. Add protective coatings to your business techniques such as spray application or electrostatic spraying enhance material efficiency as they reduce the amount of coating waste generated and guarantee full coverage. This improves performance and reduces material spending at the same time.

Alternatives for recycling also present another essential aspect. Some advanced protective coatings with high durability can be detached at the end of their lifespan and recycled, therefore reducing the waste sent to landfills.

We can achieve a more sustainable planet by investing in products that are beneficial for the environment and, at the same time, providing instrumentation and robust protection for the structures. That is ideal for companies that focus on integrity as well as responsibility.

Use of Advanced Protective Coatings in Different Industries:

Success Stories:

The use of advanced protective coatings has been successful all over the globe. Oil and gas companies use high-performance coatings to protect pipelines from corrosion. These measures reduce the maintenance costs and extend the lifespan of the pipelines.

In the marine sector, ship hulls painted with special anti-fouling paints consume less fuel. These paints inhibit the growth of barnacles and algae on the ship’s hulls, which keeps the vessels fast and economical over long periods.

The construction sector benefits as well; buildings are coated with thermoplastic polymers to increase their service life. For example, bridges are donated to receive epoxy-based applications that increase their strength and rust resistance.

Hygienic protective coatings in food processing plants help to achieve high cleanliness standards. These surfaces resist aggressive cleaning agents while safeguarding the production areas.

As shown, these advanced protective coatings have amazing benefits in all industries, especially considering their low cost.

There are anticipated innovations in the protective coating industry:

The add protective coatings to your business industry outlook is incredibly promising. The development of nanotechnology is already enabling the application of stronger, thinner layers that are more durable and add substantially less weight.

There are also smart coatings equipped with sensors that will be able to track environmental conditions, such as humidity levels and temperature. This would allow maintenance teams to be notified before potential issues arise.

Biodegradable coatings developed from green materials are also gaining popularity. This degree shift aids environmentally conscious efforts and, more importantly, helps meet increasing regulatory standards.

There is some speculation that they will develop self-healing technologies too. Imagine a coating with the ability to self-repair after sustaining damage.

As further advancements are made, these innovations point to a paradigm shift in structural protection. As fallacies caused by maintenance or service disruptions become further reduced, the focus turns to preserving the structure’s integrity and shielding it from harm.

Conclusion:

The investment in protective coatings is fundamental to maintenance. They not only serve as a barrier to restrain damage from natural elements but also aid in enhancing the aesthetic beauty of the protected structure. For instance, investing in buildings that form the base of any business would improve functionality and beauty.

With the appropriate coating, environmental issues such as corrosion and water damage could be eliminated. In the long run, this technique reduces the need to spend money on repairs and replacements.

Apart from shielding structures, there is an added advantage of these coatings serving the dual purpose of promoting branding images in an eco-friendly way.

The ability to withstand environmental issues while improving the efficacy of the building depicts the efficiency attributed to the utility of the coating. Reduced active life expenditure outlines the effectiveness of these coatings. Any unit that embraces futuristic techniques considers this investment to be a wise decision.